Taper Failures – A Hot Topic in Orthopedics

After a decade of receiving several black eyes over failed metal on metal implants, the orthopedic device industry is bracing itself for a second wave of metal failure related embarrassment.

The metal on metal debacle resulted in tens of thousands of unnecessary revision surgeries due to metal poisoning. Many of those devices were recalled and others simply “removed from the market.” The FDA weighed in as did its European counterpart suggesting that metal on metal bearing surfaces were not a good idea nor a safe alternative to metal on polyethylene. A multitude of lawsuits followed with each major manufacturer (DePuy, Zimmer, Biomet, Wright Medical and Zimmer) paying huge sums to deserving patients.

The metal on metal bearing failure was closely followed by Stryker’s recall of its Rejuvenate and ABG II implants. While these were not metal on metal bearing implants there was a metal on metal connection in the modular stem. These implants generated similar metal debris at the junction between the chromium/cobalt modular neck and titanium stem. Although the location of the failure was different, the result was the same, metal poisoning and an unnecessary revision surgery to remove the offending parts.

Now, the medical literature is reporting metal related poisoning in traditional implant designs. Even where a one-piece stem is coupled with a chromium/cobalt head doctors and scientists are seeing metal related failures. Once again, the location of the failure is different but the result is the same, metal poisoning and unnecessary revision surgery.

How could this be? Over the last ten years, the orthopedic device industry has been successfully pushing larger and larger metal heads to reduce dislocation following implant. Some surgeons have accepted the company’s premise and implanted these large metal heads in thousands of patients. Truth be told, when you talk to experienced, well trained surgeons, dislocation is virtually a non-issue. It should occur in less than 1% of the patient population. So, the industry created a solution to a problem that did not exist.

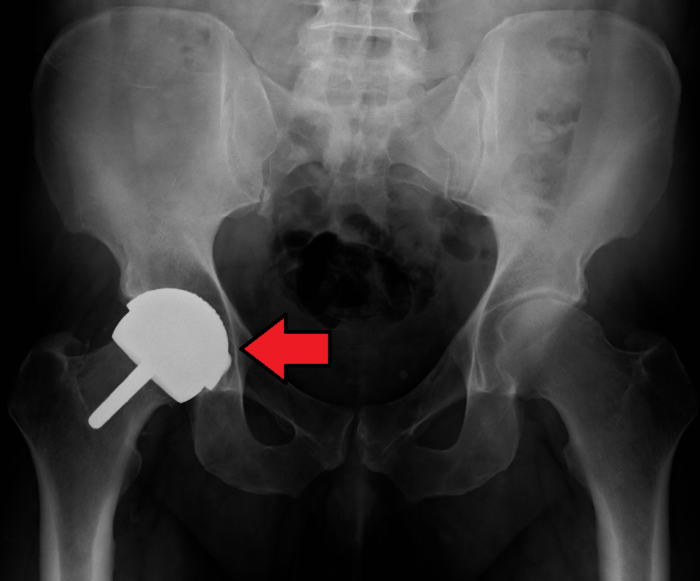

Why do larger and larger metal heads create a risk of metal related failure? Current thinking suggests these larger heads create significantly more rotational torque at the connect point between stem and head. All modern heads seat on the stem at what’s called the trunnion. Despite the ever increasing size of the metal heads, trunnions have remained the same or have even gotten smaller. More torque = more motion. Motion at this connection is not good. The failure mode is complicated but motion causes the chromium/cobalt head to corrode or rust using layman’s terms. Once that process begins metal wear debris and the byproducts of metal corrosion get into the tissues surrounding the implant and into the bloodstream. This can cause tissue and bone death and several potential systemic problems. The body needs small amounts of these metals. However, the corrosion process in these implants generates toxic levels of metal.

There are now four independent reports in the medical literature of multiple catastrophic failures where the heads corrode so much they start toggling on the trunnion. Once that process starts the head grinds the trunnion down and ultimately falls off of the stem. The medical term used for this is spontaneous dissociation. That event triggers a surgical emergency for removal and replacement of the stem and head. These reports all involve Stryker’s Accolade TMZF stem and its LFIT-V40 chrome/cobalt heads.

When discussing this issue with surgeons, they routinely suggest this is not just a Stryker issue. Those who frequently do revision surgery have seen trunnion failures across manufacturers’ implants.

Every major manufacturer of implants has sold hundreds of thousands of larger metal heads worldwide over the past ten years. This is so despite the ever increasing trend to use ceramic heads as an alternative. Because of this problem, many surgeons will not implant a metal head and if they are forced to do so because of insurance issues, the head will be 32 millimeters or smaller in size.

Share This